Extraction Technologies

Saskatchewan uses a wide variety of extraction technologies to extract light, medium and heavy oil and is increasingly pursuing harder to reach oil whose production is more energy and water intensive. Thermal technologies such as Steam Assisted Gravity Drainage and Cyclical Steam Stimulation (see below) are primarily used to extract heavy oil in the Lloyminster region. Multi-stage hydraulic fracturing is primarily happening in the Southeast (Bakken formation); around Shaunavon (Lower Shaunavon formation); and around Kindersley (Viking formation). In addition to the technologies profiled below, industry also uses a number of enhanced oil recovery techniques such as carbon flooding, (using C02 piped in from North Dakota and from Saskpower's Boundary Dam plant) water flooding, and many more.

Saskatchewan contains oil sands in the Axe Lake area north of La Loche. These leases are owned by Cenovus Energy Inc. Although commercial production was slated to begin in late 2014, thus far they remain undeveloped commercially.

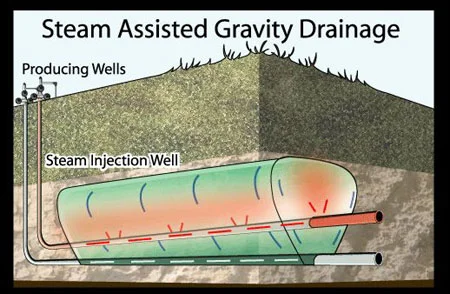

Image courtesy of the National Energy Board

Hydraulic Fracturing (“Fracking”)

There are two types of hydraulic fracturing. Saskatchewan has been using single hydraulic fracking treatments on vertical wells since the 1950s (there are over 35,000 such wells in Saskatchewan). The newer technology of multiple fractures along horizontal wells, called multi-stage horizontal fracking, has been used in the province since the mid 2000s with more than 7,000 such wells in the province.

In hydraulic fracturing, a fluid (usually water) mixed with proprietary chemicals and sand is pumped down a well and into the targeted formation until the pressure builds and fractures the surrounding rock. The sand then props open the fissures and allows small pockets of oil trapped in the surrounding rock to flow to the well.

Note: In Saskatchewan multi-stage fracking is used to extract OIL, not gas.

Risks and Impacts: In Saskatchewan the targeted formations are relatively deep. Fractures are, thus, spatially distant from fresh water aquifers. However, risks to freshwater still exist from the possibility of well casings breaking down and oil and/or associated gas leaking into aquifers. Multi-stage hydraulic fracking uses a lot of water – around 750,000 gallons (see p.45 of this document) on a multi-stage frack in Saskatchewan. Water is lost to the hydrological cycle when it stays deep underground or when it is disposed of into deep formations after flowing back to the surface during production. Multi-stage fracking also has a relatively large surface impact since there is more equipment on the drilling site and since this equipment stays on the lease for longer than conventional drilling.

In other jurisdictions there is now good evidence that fracking causes earthquakes. Saskatchewan has a relatively stable geology, however over-pressurizing of reservoirs used for disposal could induce seismicity.

In Saskatchewan companies are not required to report on the contents of their fracking fluids, so we are unaware of the toxicity of the chemicals being used for fracking.

Image copyright the Heritage Community Foundation

Steam Assisted Gravity Drainage (SAGD)

In Saskatchewan, SAGD is used to extract heavy oil (in AB it is also used to extract oil sands). Steam is injected into the top well, heating up the surrounding oil and sand. This makes the heavy oil less viscous and allows it to drain into the lower well where it is pumped to the surface.

Risks and Impacts: SAGD requires large amounts of fresh water and heat (usually produced in a natural gas fired plant close by). Although some of the water can be reused, SAGD is still very water and energy intensive. Some freshwater is lost to the hydrological cycle either when it is disposed of as wastewater into deep disposal wells, or when it stays in the producing zone underground. The physical footprint of SAGD is quite large because of the steam generators and the water and oil tanks that require space on leases. The physical surface impact harms vegetation and wildlife by fragmenting habitat. Heavy oil is also dirtier than light oil and requires more upgrading.

Illustration of the Cyclic Steam Stimulation Process. Courtesy of the Canadian Petroleum Producers

Cyclical Steam Stimulation (CSS)

In Saskatchewan, Cyclical Steam Stimulation (CSS) is also used to produce heavy oil in the Lloydminster area. In CSS one well goes through the three stages depicted to the left.

Risks and Impacts: The risks and impacts of CSS are very similar to SAGD. Large amounts of fresh water and energy are used to produce the steam and the physical imprint of production is relatively large.